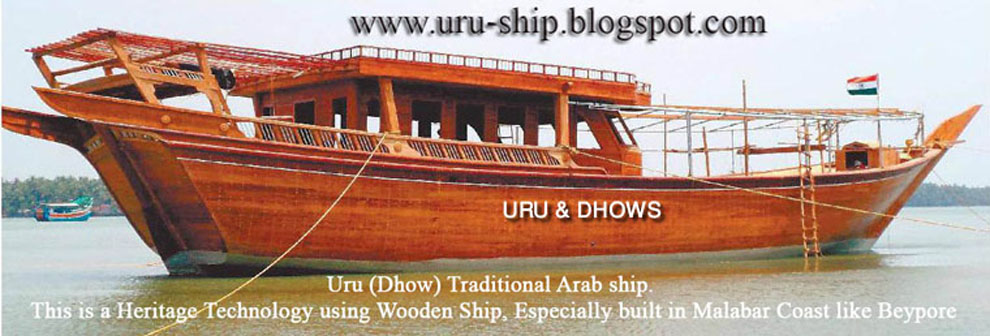

The Dhows of Beypore - Uru:

The name Uru is associated with the traditional ship

building culture of Kerala. And the art and science of making these ships came

from the Arab world, some several centuries ago. The Arabs called them Dhows

and they eventually became the traditional Arabian trading vessels. Centuries

ago, Arab traders traced their way to the spice-scented shores of Kerala. And

after coming to know about the availability of good timber in the forests of

Kerala and also the presence of skilled crafts persons in ship building, the

Arab merchants began to place orders for constructing dhows to the crafts

persons of Malabar in north Kerala.

Located at the mouth

of the Chaliyar River Western Asia for ships, because of its fame as the home

to excellent crafts persons. This shipbuilding industry at Beypore once had a

healthy phase of growth until the invasion of iron and steel, posing a serious

threat to its existence.

The Baraami’s were the ship builders in

Beypore. Local teak wood was used for manufacturing the dhows. These Baramis

can be traced to the Al Mukalla tribe in Egypt

Beypore was where the great

Urus and the tough Dhows were built. They were the mainstay of the spice trade

between the sea coasts of Malabar & Arabia. Here was where master craftsmen

(Maistry) or the carpenter breed called Khalasis crafted these wonderful ships

with the aid of no modern tools like charts or instruments, but from memory

& mental calculations. The old ships were crafted from Malabar teak but

sadly now import a variety similar to Irul, from Malaysia Chaliyar River

It was from these Malabar

shores that the first migrants to the Gulf launched themselves on a long

lasting exodus, when young men desperate for jobs smuggled themselves out of

the country in long country boats called uru’s which took cargo to the Gulf

ports.

The Beypore area is today

home to the Mappila khalasis, famous for their expertise in lifting heavy

weights. Till today, when machines and bulldozers fail, the khalasi teams are

called on. Using little more than a wooden pole used as a dower or winch and

leveraged by hawsers and pulleys, they move and lift huge masses. The Mappila

khalasis were traditionally employed in launching the 400 tonne Arab dhows built

at the Beypore docks but now are masters in hauling heavy wrecks.

An exciting fact about the

shipbuilding industry in Beypore is the way in which the craft are built and

the variety which can be found. The flat bottomed zambuk (Sambuk), the majestic breek

(both Indian and Arabian designs), the boom which boasts of an enormous cargo

carrying capacity, and the bahala with its beautiful and intricate carvings and

arches, are all made using traditional tools and techniques. Even more

incredible is the number of people dependent on this industry. More than 500

families are directly and indirectly dependent on the shipbuilding industry.

Special methods used from historic times were the use of wooden dowels instead

of nails, use of coir rope and tar to seal joints etc.…Duarte Barbosa first recorded (around 1500 AD)

manufacture of keeled ships boats carrying 1200 bahares burden (some 400

tonnes) in Beypore. He also noted that they had no decks. They were classic

sewn boats of teak wood (both of which were at that time only available in

Malabar – in this context). The caulking was done with shavings off the palm

trees and the ships were coated with shark oil or castor oil for waterproofing.

It was the previously

described people from Oman , Hadhramaut, Yemen

& Gulf – Iran Kuwait

and Qatar

A remarkable feature of the

technology of Uru making is that, there are no documents, work plans, technical

data sheets or drawings right from the concept stage to completion. The

construction details are assigned on a day to day basis to the assistants and

carpenters by the master carpenter or Maistry. No electrical tools or heavy

machines are used. The basic tools are the indigenous carpentry tools. All

heavy lifting is done using elaborate pulley systems. Another amazing feature

is the pre calculated water line marked around the hull, will be precisely on the water-level while

the boat is launched. The master craftsmen of khalasis apparently use certain Shlokas (or are they Arabic verses?) as their guide to ship

building. Even today, the formula of dhow making remains a closely guarded

secret that is handed over from generations to generation. Today, only as few

as four master craftsmen are left behind.

Today Beypore dhows used for

tourism purposes Dubai

Various types of ships were

built in Beypore. Some of them were: Boumb , Padavu , Bireek , Kottiya ,

Sambook , Bahla & Pathemar . The Beypore ships were usually around 300

tonnes and sometimes 600 tones. Today’s manufacturing methods are slightly

different – Nails are used. The ‘Keel’ is the first part of a

dhow to be made. The second phase of work is concentrated on the second layer

of the dhow from the bottom called ‘ganel’. Iron and copper nails are used to

hold the wood together. Filling the gaps using quality cotton is the next

tiring phase of work. It is a very time consuming process that has to be done

with absolute care. Making of ‘chukkan’ is the third part of the construction.

The ‘Chukkan’ begins from the keel itself and its height would be the actual

height of the dhow. ‘Chukkan’ provides the total control of the vessel. Then

the inside part of the dhow ‘deck’ and, finally ‘aruthi’ is made. The manufacturing

process is completed with the tying up of the sail ‘mat’ (paya) to the mast

(chamaram).

The launching of a ship is a

festive ceremony, attended by a large number of people. First, a prayer is said

by the Qazi. When a Dhow was ready for launch wooden planks were kept up to

appropriate height. The logs of the Puvathi tree serve as rollers are put on

either side. Over these roller beams (Balus) strong enough to support the ship

are kept. The gap between the beams and ship are filled tight with ropes. Then

the ship is allowed to slowly move over the rollers with the help of rope and

pulleys. In water they dip exactly up to the water mark earlier drawn by the

Baramy. After the successful launch, a feast is laid out for all who have

contributed to the ship building effort.

There is a light house too, at Chaliyar, just near Beypore.

Really it's an art by Kerala experts. No doubt in that..you will get the sample art work in www.nimton.in

ReplyDelete